Broader, deeper and easier grasp of

production information.

The i-Connect production quality control system is a core application for the construction of IoT at manufacturing sites, integrating information from molding machines, peripheral equipment, and various sensors. It dramatically improves monitoring and control capabilities for the whole molding cell to achieve higher-level, borderless, efficient production.

"Dramatically improves"

monitoring and control

capabilities - powered by i-Connect

A broader

grasp of information

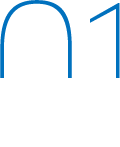

Intuitive control on the whole plant using an overview list

Icon placement that matches the plant layout allows understanding of the operational status of each machine in an instant.

It is also possible to display a list of operation transition or production progress graph for each machine.

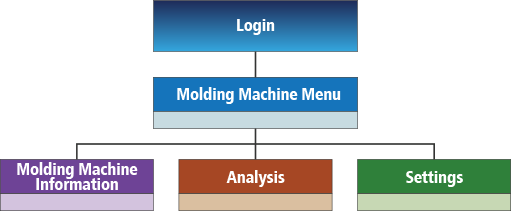

Molding Machine Menu

Molding Machine Menu- Displays all registered molding machines in each plant. The layout can be changed at any time, and the background image can also be set (floor layout etc.).

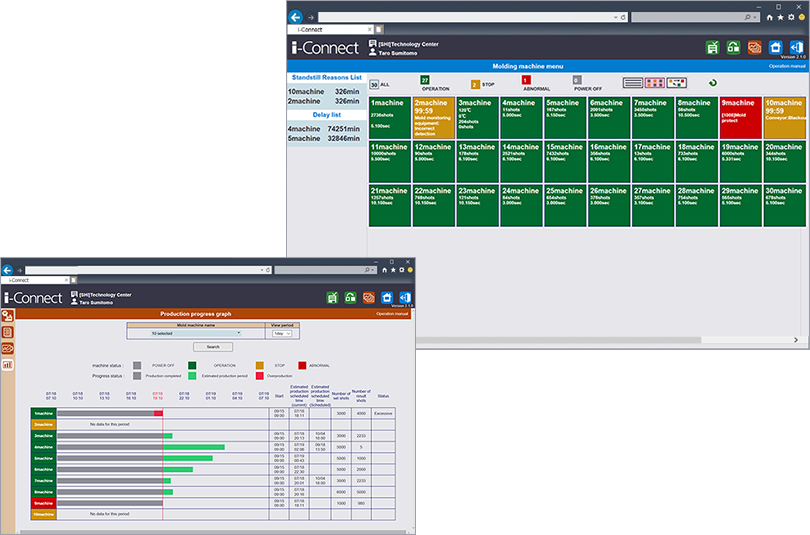

Production Progress Graph

Production Progress Graph- The status and progress of the selected molding machines are displayed using bar graphs.

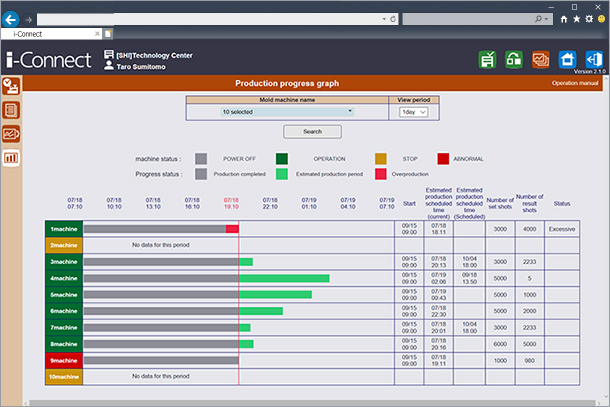

Real-time understanding of the whole molding cell

Acquires data such as temperature, operating status, etc. of peripheral devices, and displays them in a list.

Separate molding machine option(s) might be required for connection with peripheral devices and sensors.

Peripheral Device Checking

Peripheral Device Checking- Displays the operating status and numerical data for peripheral devices connected to the selected molding machine. This allows upper and lower limits to be set, and issues warning when the monitored value is out-of-range.

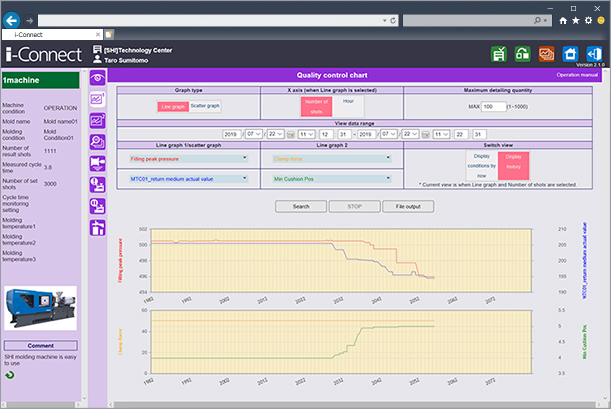

Quality Control Chart

Quality Control Chart- Understanding of the relationship between the actual temperature of the mold temperature controller and the filling peak pressure of the molding machine is also possible by comparing graphs.

A deeper

grasp of information

Improved traceability

By specifying time frames, detailed chronological data such as transition of operational status

and correlations can be checked. Tracing machine status and molding conditions at a particular time

from a molded article improves product traceability.

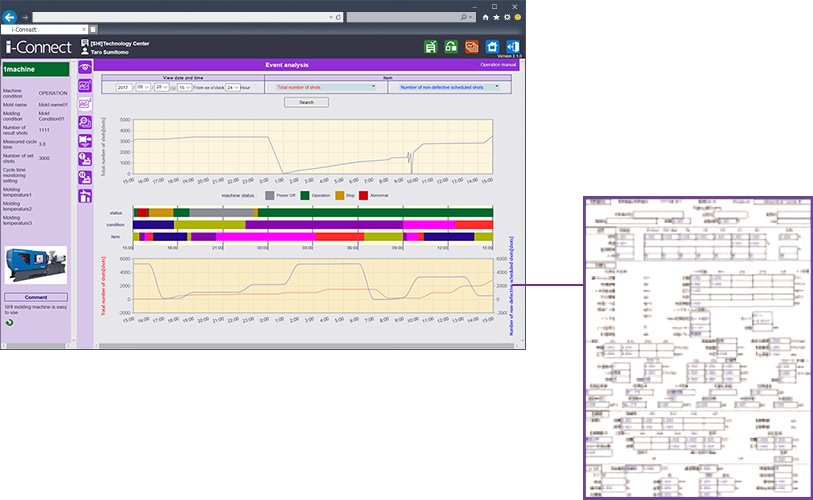

*Image is blurred on purpose.

Event Analysis

Event Analysis- Molding machine status, items, and condition alterations are displayed on a graph, and events searching is possible.

Calling and verification of molding conditions are possible.

*Image is blurred on purpose.

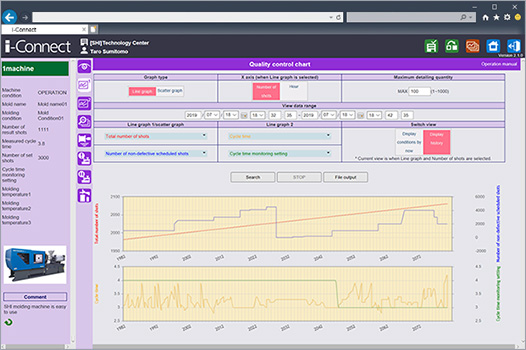

Data analysis of a single molding machine

By specifying the number of shots, transition in actual values such as mold clamping force, peak pressure, cushion value, dosing time can be confirmed using line graphs and scatter diagrams.

Quality Control Chart

Quality Control Chart- Displays data in graphical form for the selected molding machine.

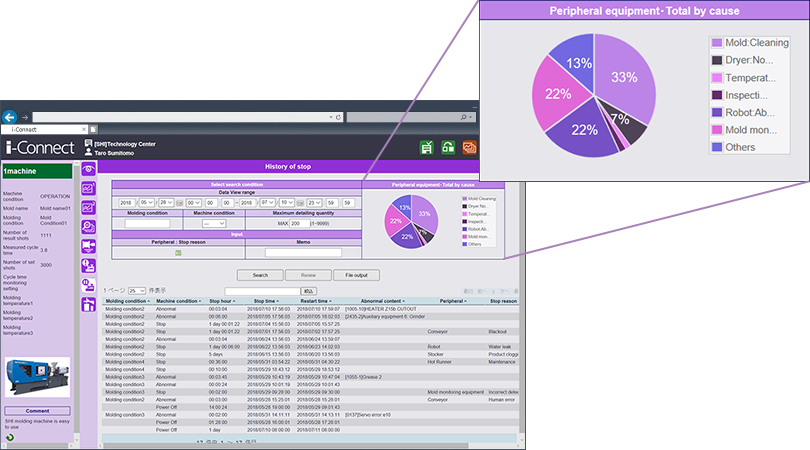

In-depth history management

Using stoppage history, alarm history, and molding conditions history allow analysis of factors correlated with defects, which can lead to improvements in production conditions.

Allows input and analysis of the causes of stoppage.

Stoppage History

Stoppage History- Displays the stoppage history of the selected molding machine.

An easier

grasp of information

Speedy error handling

Linkage of alarm number to troubleshooting.

This enables rapid on-site error handling.

Alarm History

Alarm History- Displays the alarm history of the selected molding machine.

This feature applies only to SE-EV, SEEV-A, and SEEV-A-HD series.

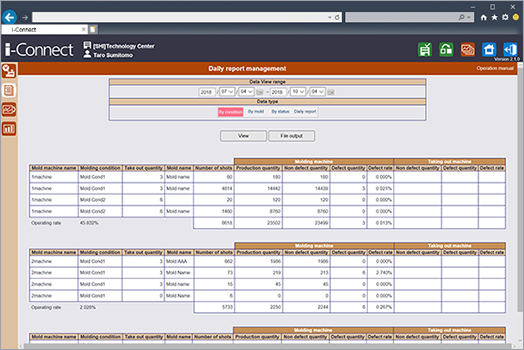

Accurate, simple creation of daily reports

Automatically summarizes daily reports for each molding machine, and exports these as CSV file through simple operation.

Daily Report Management

Daily Report Management- Displays daily reports based upon operating data of molding machines.

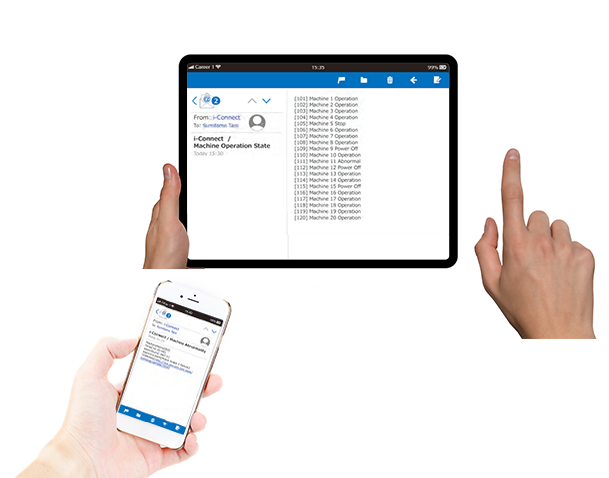

Real-time access to information away from the plant

Real-time notifications of operational status and errors can be sent to devices such as smartphones and tablets, even at off-site location.

Simple operation

Browser-based application means that there is no installation required.

The graphical screen design supports intuitive, speedy operation.

- Coloring by category

- Theme color is configured for each main item, providing an easy-to-understand screen configuration.

Dashboard

Dashboard- Summarized information for the selected machine is

displayed as a list on screen.

Linking work sites with administrators and conference rooms

As long as there is a device, anyone can obtain an understanding of the real-time production status from anywhere, at any time.

Production sites centered information networks are establishing a new method for quality control.

i-Connect transmits process data and enables production

information control and monitoring.

The i-Connect production quality control system is a core application for the construction of IoT at manufacturing sites, integrating information from molding machines, peripheral equipment, and various sensors.

The i-Connect solves problems at the molding site.

IoT refers to a system that connects various devices to the internet, providing mutual control by information exchange. Integrated control system fully incorporating IoT is attracting attention as a new method of production innovation.

The MES (manufacturing execution system) is to be prepared by the customer.